Essential Details About Carbide Burrs

Carbide Burrs: Precisely what are They provided of?

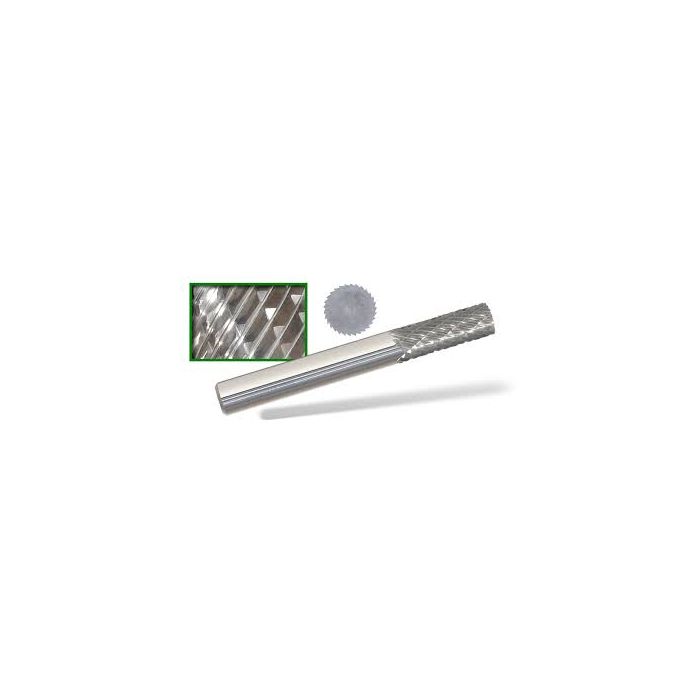

These aren’t the standard bits that you’d used in drills and impact drivers. They’re made of tungsten carbide, an alloy of tungsten and carbon and exhibit exceptional properties. The alloy is perfectly up to thrice as hard as steel and possesses the best compressive strength associated with a known metal.

Additionally, it is highly resistant to deformation, holds a unique against high temperature, has exceptional impact and abrasion resistance and it is second and then diamonds because the hardest material there’s. Tooling them requires some serious CNC machining considering how hard they are.

Carbide Burrs: Materials on Which They’re Used

Hardness and sturdiness are where your typical die grinder bits run circles around any devices being offered. These things are meant to last and produce consistent results whatever they’re suited for. This may cover anything from commonly-used metals such as stainless-steel, iron, aluminium and copper, gold and silver coins like gold and silver coins, as well as a great deal of plastics, to harder materials like ceramics, tiles, gemstones and masonry.

They also make easy work of both hard and softwoods. Surpassed in outright hardness only by natural and synthetic diamonds, the bits exhibit substantially longer run times than comparable burrs optioned in HSS steel, won’t show warning signs of wear or metal fatigue on account of high working temperatures, and could be used without issue at real high RPMs.

Carbide Burrs: Who’re They for?

Bits attached to the end of die grinders and also other rotary tools are used across an array of varying professions and fields. Frequently this means anyone working together with metal and wood. They may be basic necessities for metalworkers, welders, smash repairers, tool makers, plumbers, and mechanics, along with woodworkers, carpenters, joiners and construction workers.

Moreover, the bits can certainly drill into plasterboard, brick and concrete. This list can even be populated with less obvious professions. Smaller bits are utilized by artists, sculptors, jewellers and dentists. Lastly, the attachments are helpful in a household or commercial work that will require general material removal, smoothing and cleaning.

For more details about SB-1 Carbide Burrs check out this popular site